👀. What is a door bottom seal?

Door seals are accessories, used to cover the openings at the bottom part of the door. They can be used for all types of doors to block unwanted bottom openings.

When the doors are hinged, a gap is provided from the floor level for the easy swing of the door. If the door lacks a threshold in its frame, you will find openings at the bottom part, which is unavoidable.

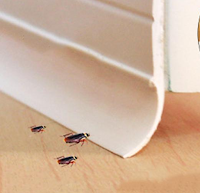

So, to cover these openings without disturbing the operation of the door, we use a door seal as shown in the image below.

The bottom door seals are also known by the names bottom door sweeps or bottom door shoes.

👀. Why do we need bottom door seals?

The door seals are needed

1. To prevent the entry of insects & cockroaches from the door bottom.

2. To block the breeze or cool air from entering the room.

3. To avoid the light from entering the building.

4. The door seal helps to block the sound from the adjacent room to a certain extent.

5. To block the wastage of energy from air-conditioned rooms.

👀. How to install door bottom seals?

For aluminum door sweeps:

1. The bottom width of the door is measured with a measuring tape.

2. The aluminum strip of the door seal is marked to the required door size & cut by using a hacksaw or cutter tool.

3. The vinyl sweep is cut to the size & slid into the aluminum strip.

4. The aluminum strip is screwed to the bottom door part so that the vinyl sweep touches the floor surface.

For adhesive door sweeps:

1. Instead of screwing, the self-adhesive strip of the door sweep is fixed to the door bottom.

2. Before installing, the door bottom surface should be cleaned or washed for good bonding.

For double draft & strip door seals:

1. They are fixed at the door bottom by sliding action without much effort.

All types of bottom door seals are DIY attachments, consuming lesser effort & time for installation.

👀. What are the different types of door bottom seals?

There are 5 types of bottom door seals.

1. Aluminum door sweeps:

a. Brush door sweep.

The aluminum plate or strip is attached with a nylon brush which can be easily detached by sliding. The brush sweeps & cleans the dust beneath the door. The brush also blocks the door's bottom opening. The drawback of brush sweeps is they wear out over time & are not efficient when compared to flat door sweeps.

b. Flat door sweep.

Instead of a nylon brush, the aluminum plate is attached with a rubber base to seal the opening. They have a royal look when compared to the brush door sweep. Other than rubber, the base materials used are silicone & vinyl, having varied colors.

2. Adhesive door seal:

These types of door seals do not have separate aluminum strips to hold the sealing base. The door seal is stuck to the door bottom by self-adhesive strips.

3. Double draft seals:

The fabric sleeve holds the foam cylinder on both sides of the door. When the door is moved, they easily glide over all types of floor surfaces. These types of door seals also act as door stoppers.

4. Strip door seal:

All types of strip door seals work well for the smaller door bottom openings. If your door opening is above 6mm., then strip door seals are not a suitable choice. They are available in different shapes like L- shape, V-shaped, & E-shaped designs. This is the best-chosen option for the glass doors.

5. Weather stripping:

If you are thinking of sealing all your door & window gaps, then this will be the cheaper option. Weather strips are available in larger-length rolls at a better price. You have to peel the back of the adhesive strip & stick it to the gap surface wherever necessary.

To go through all types of building materials used in construction, click here.

Thank you for going through this article❤. Have a good day 😄.