Following are the 11 points that should be checked in the column reinforcement work before concreting.

1. Quality of bar:

2. Grade of steel:

The grade of the steel bar should be chosen, as mentioned in the reinforcement detail drawings. You can find the grade of steel embossed over the bar, as shown in the above image.

Checking the steel grade is a must, as it indicates the yield strength & decides the load-carrying capacity of the rebar.

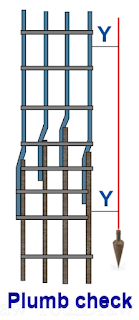

3. Plumb check:

The column reinforcement should be checked for its verticality so that the clear cover should be uniform from the shuttering formwork.

There should not be any twist in the tied reinforcement bars when compared at the top & bottom end of the rebar.

4. Clear cover:

The column cover blocks should be used to maintain the equal clear cover as mentioned in the drawing.

If you are using circular cover blocks, care should be taken to insert them in the lateral ties at the required intervals to maintain a clear cover from the concrete.

5. Diameter & spacing of bar:

6. Dia. & spacing of lateral ties:

The diameter & c/c distance between the lateral ties should be checked before erecting the formwork. The lateral ties should be perpendicular to the main bar & there should not be any ups & downs in their periphery.

7. Hook length:

8. Lateral tie position:

9. Development length:

The development length of the column reinforcement should be checked for its proper length as per the drawing, to achieve the designed bond strength.

10. Bar lapping:

The lapping of the bar should be staggered as shown above. The top end of the column bar should not be at the same level if further lapping is needed for the column extension.

Go through: What is lap length in reinforcement bars?/ General rules while providing lap length.

11. Binding wire:

Once the binding wire is tied at the corner of the lateral ties, the wire knot should not be protruded into the concrete cover area. Give instructions to the workers to push them within the reinforcement area, so that the construction quality is maintained.

For you 👇

❤ Different types of rebar ties/Different ways of tying rebar with binding wire.

Thank you for going through this article❤. Have a good day😄.

No comments:

Post a Comment