Following are the 10 points that should be checked in the beam shuttering work before concreting.

1. Formwork quality:

The minimum thickness of the plywood should be 12mm. for the beam formwork. For the heavier structural beams, plywood of thickness 18 mm. or above should be used to avoid bulging.

The plywood should be fastened with adequate wooden batten ( Patti ) at the appropriate intervals as shown above. The inner surface of the shutter mold should be clean & even, without having any concrete particles adhered to it.

2. Shuttering oil:

3. Beam size:

The length, breadth & depth of the individual beam as required should be checked at both ends of the beam. By using the string line, the top edge of the shutter should be checked for its alignment & straight line.

4. Plumb of vertical formwork:

The formwork of the beam should be checked for its verticality by using the plumb bob or spirit levels. The measurement of the string distance should be taken from the plywood surface at the top & bottom levels of the formwork. The shutter should be adjusted for its verticality until we get an equal measurement (say y ) at the top & bottom plywood area.5. Soffit level:

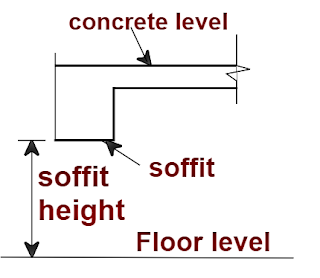

The level of the soffit formwork should be checked on both axes by using the spirit level as shown above.

The level should be checked at both the ends of every individual plywood shuttering ( usually 8ft. ) or at the joining area of the two formwork.

6. Beam position:

The position of the beam shuttering should be confirmed by measuring the distance (as required ) from the beam next to it or from the edge of the slab.

As you can observe in the above drawing, the position of beam A should be confirmed by checking the distance X & Y from the beam existing on either side of it.

7. Beam level:

The soffit height from the floor level should be checked by using a level tube or auto-level instrument. The finishing level or top surface of the concrete level ( slab level ) should be marked over the formwork beforehand.

8. Beam support:

9. Gaps or openings:

If there are any gaps or openings in the formwork, the cement slurry comes out through those gaps at the time of vibration. So, if you find any openings in the shuttering, they should be properly sealed. Smaller gaps can be filled effectively by using pieces of rubber or foam sheets.

10. MEP check:

MEP stands for mechanical, electrical & plumbing works. If any conduits, sleeves, or pipes pass through the beam formwork, they should be properly installed beforehand by making cuts & groves in them.

👀 To go through all types of construction-related procedures & checklists, click here.

No comments:

Post a Comment