Field test for the solid concrete blocks

|

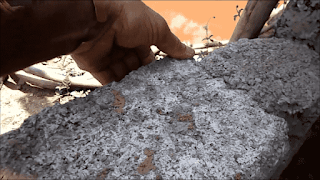

| Solid concrete blocks Fig. 1. |

You can check the quality of the solid concrete blocks on site by following some simple methods as given below.

1. Drop test

Randomly select one block from the total no. of blocks of the particular batch. Lift the block at about 4 to 4.5 feet which is nearer to your chest level and drop it on the hard ground surface.

Vertical drop:

The length of the block should be kept in a vertical position before dropping it on the ground. The concrete block should be intact in shape without any damage after crushing over the ground surface. If the sample block breaks into pieces or develops a crack then it is better to reject such concrete blocks.

Horizontal drop:

You have to hold the concrete block with the length of the block in the horizontal position as shown in fig. 2. From the same chest height, you again drop the block on the hard surface. If the block breaks into no. of pieces, then such blocks can be considered low-quality blocks.

|

| The horizontal dropping of concrete block. Fig. 2. |

2. Corner test

Press the corner of the block with your thumbnail on all eight sides one by one as shown in fig. 3. If it gives out or if some particles are broken from the edge, then you can classify such blocks as of low quality.

|

| Pressing the corner of the concrete block. Fig. 3. |

3. Chisel test

This is a comparative test for the two or more sample blocks collected from the different production units to recognize the manufacturer, who delivers the best quality blocks.

Cut the groove into the solid concrete blocks, horizontally running on all four sides of equal depth by using chisels as shown in fig. 4. It should be cut at the center of the block until the block separates into two pieces. In this test, you will find the quality of the blocks by the three actions.

Hardness:

If it is harder to chisel the block and if it takes more time for cutting out in comparison to all other sample blocks, then it gives you a hint that the blocks of that particular batch are of good quality.

Groove depth:

Measure the depth of the cutting at the time of separation of the block. If the depth of the groove is more in comparison, then that block can be considered of good quality.

Breakage:

If the block breaks into several pieces during this process, then it is better to drop that batch of the block from your list.

|

| Chisel test for the block. Fig. 4. |

4. Nail test

This is also a comparative test similar to the chisel test. You have to hammer a nail into the sample blocks on three or more points. This action will provide you with the following data for the block selection.

Resistance:

If the block resists the insertion of the nail and if it is harder to hammer a nail then you can position that block above all other different samples which exhibit low resistance.

Grip:

If the block provides a good grip on the nail by restricting its movement, it is also an indicator of the block's quality.

5. Texture

The blocks should have a grainy surface texture which you can observe in fig. 1. If the concrete block has a smooth texture finish then it indicates more quarry dust content in its mix proportion.

The dust weakens the concrete strength which in turn results in a block production of low compressive strength.

6. Shape & size

The block should have a uniform shape with sharp edges. The difference in the dimensions on the two similar sides at both ends should not be more than ±3 mm. (allowance).

To go through the field & laboratory tests conducted in civil engineering, click here.

Thank you for going through this field test ❤. Have a good day 😄.

.png)

%20(1).png)